Everything You Need to Know About Custom Laser Cutting

Custom laser cutting has revolutionized the way industries approach fabrication, offering an unprecedented level of precision and efficiency. This versatile technology is increasingly being utilized across various sectors, from automotive to fashion design, thanks to its capability to produce detailed and intricate designs. Whether you are a hobbyist, a small business owner, or a part of a large-scale manufacturing operation, understanding the nuances of custom laser cutting can be invaluable in optimizing production processes and achieving superb results.

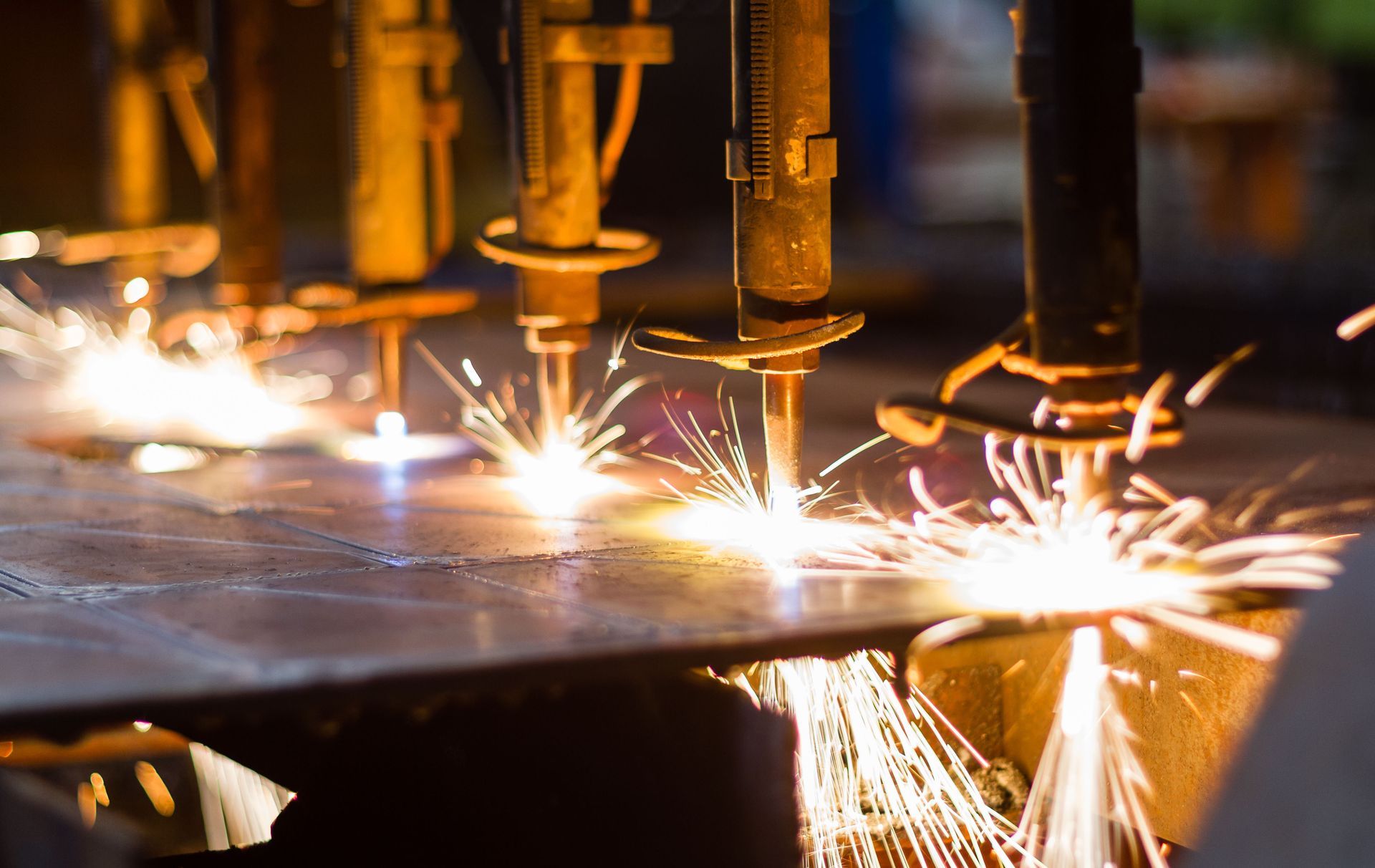

Understanding the Operation

The process of custom laser cutting utilizes a focused laser beam to cut through materials with remarkable accuracy. The technology can accommodate a wide array of substances, including metals, plastics, wood, and even textiles, making it highly beneficial for diverse applications. The level of detail achievable with laser cutting is tremendous, allowing for clean lines and smooth edges, which are critical for the aesthetic and functionality of the final product.

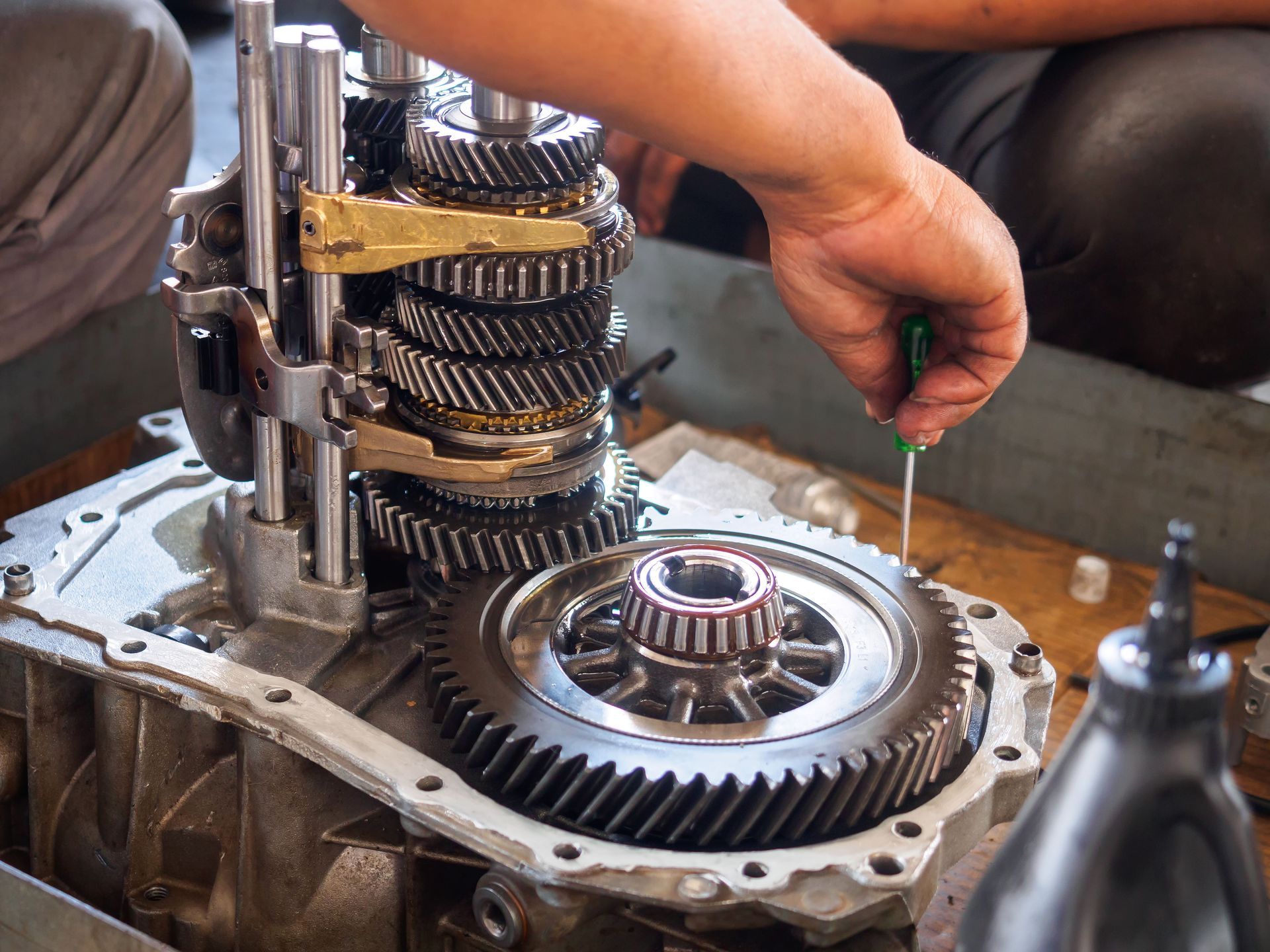

Assessing the Advantages

One of the primary advantages of custom laser cutting is its efficiency in material usage and reduction of waste. Unlike traditional cutting methods, laser cutting minimizes scrap material due to its precision. According to Mavin Industries, more than 50% of all products that we have around us require either some form of fabrication or some form of welding. This statistic highlights the importance of technologies like laser cutting, which streamline these processes, ensuring optimal use of resources and time.

Analyzing Customization Capabilities

Additionally, the integration of design software in laser cutting processes offers significant flexibility and customization capabilities. Designers can create complex and unique patterns digitally, which are then replicated with high accuracy by the laser cutter. This flexibility not only shortens production time but also allows for easy modifications and rapid prototyping, empowering businesses to bring innovative products to market faster.

Custom laser cutting is a technological advancement that significantly enhances the capabilities of modern manufacturing. By offering superior precision, reducing waste, and providing considerable design flexibility, it addresses many challenges faced in fabrication and production. As industries continue to evolve, the adoption and understanding of custom laser cutting will likely play a crucial role in shaping the future of manufacturing, ensuring that businesses can remain competitive in an ever-changing landscape. To explore your custom laser cutting options, reach out to Denali MetalWorks today to get started!

service Area

Phoenix, AZ

Tucson, AZ

Flagstaff, AZ

Phoenix, AZ Metro Area

Arizona

Share On: